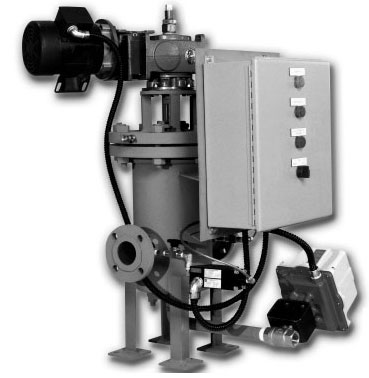

Automatic Self-Cleaning Strainers

Pressures to 740 PSIG (51 BARG)

Temperatures to 400ºF (204ºC)

|

Features

| |

Materials

| End Connections

| |

Ratings

| Sizes

|

Industrial Strainer News

Greetings:

Effective October 15, 2018, SSI Fabricated has been acquired by The Hellan Strainer Company, an IMC company.

Going forward,

Please issue purchase orders to the following:

Vendor Info: SSI Fabricated

a div. of The Hellan Strainer Company

2860 Cincinnati-Dayton Road, Suite B

Middletown, OH 45044

PH: (513) 217-3535

Highlights

Auto-Cad Inventor Engineering base

ASME Section VIII Div.1

ASME B31.1 Design Code

Non-Destructive testing

- X-ray

- Dye Penetrant

- Hydrostatic testing

- Ultrasonic wall thickness

- Wet Florescent Mag Particle

On site key equipment

- High Tech, Positioner based - “Pulse Arc” Welding stations

- Plasma Cutting Table

- Bead Blaster

- Paint Booth